The quantity of waste tires continues to increase with the development of the automotive industry, and how to efficiently and environmentally treat these waste tires has become a global focus of attention. The waste tire processing equipment adopts high-temperature pyrolysis technology, which can effectively achieve the reduction, harmless treatment, and resource utilization of tires. This device separates impurities such as moisture and organic matter from waste tires through high-temperature cracking reactions, while thoroughly extracting rubber, steel wire, and nylon fibers, providing a new way for the recycling of rubber resources. During the processing, no pollutants such as dust, exhaust gas, and wastewater are generated, ensuring environmental safety.

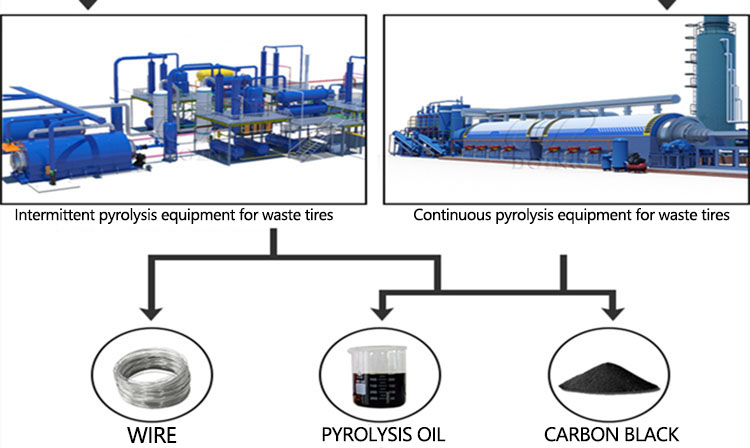

Waste tire processing equipment can be divided into two forms: continuous and continuous batch processing. Continuous equipment can achieve uninterrupted feeding and discharging, suitable for large-scale industrial production, while continuous batch equipment is suitable for small and medium-sized enterprises or intermittent production needs. Regardless of the processing form, the equipment adopts an advanced PLC intelligent control system to achieve one click start, automatic monitoring, and remote control, greatly reducing manual intervention and improving operational efficiency. The automated operation mode enables enterprises to reduce labor costs while ensuring production stability and safety.

The device has multiple significant advantages. Firstly, it can achieve efficient and continuous processing, greatly improving production efficiency. Secondly, the equipment strictly follows environmental standards to ensure the harmless treatment of waste tires, which will not cause pollution to the environment. In addition, the equipment operates stably and has high safety, equipped with comprehensive protective measures, and can operate reliably for a long time. At the same time, the efficient separation technology of the equipment can ensure high-quality recycling of products such as rubber oil, carbon black, and steel wire, enhancing the market value of renewable resources. More importantly, the equipment adopts energy-saving design, with low operating costs and long energy consumption life, making the investment return more considerable.

The resource utilization value of waste tire processing equipment is very prominent. After pyrolysis, waste tires can be decomposed into rubber oil, carbon black, steel wire, and nylon fibers. Among them, rubber oil can be used as industrial fuel oil or refined into diesel, carbon black can be used to produce rubber fillers, paints, plastics, etc., steel wire can be directly sold or melted back into new steel, and nylon fiber can be used to manufacture recycled plastics or geotechnical materials. The recycling and utilization of these high-value products not only reduces the harm of waste tires to the environment, but also reduces dependence on primary resources, providing strong support for the development of circular economy.

In the context of the "dual carbon" target, waste tire processing equipment is undoubtedly an important tool for promoting the development of green industries. This device can help businesses achieve sustainable development, improve economic efficiency, and fulfill social responsibilities. A large amount of waste tires are generated globally every year, and if not treated properly, it will cause serious pollution to the environment. By introducing advanced waste tire processing equipment, not only can environmental pollution be reduced, but considerable economic benefits can also be created. For enterprises that hope to take the lead in the field of waste tire resource utilization, actively introducing and promoting this efficient and environmentally friendly treatment technology will be an important measure to achieve green development.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Waste tire processing equipment, efficient and environmentally friendly resource utilization solution,Waste tire processing equipment,YONGLE GROUP

Latest news

Latest news