The treatment of urban and rural domestic waste has long been a public concern. Henan Yongle Group's newly developed domestic waste processing equipment addresses this challenge through an oxygen-free low-temperature continuous pyrolysis process, achieving synergistic harmless treatment and resource recovery. Operating under fully enclosed conditions, this technology effectively blocks the formation of harmful substances like dioxins while converting household waste into high-value resources, establishing a sustainable pathway that combines environmental and economic benefits.

The core operational mechanism lies in precise control of pyrolysis technology. Processed in an oxygen-deprived sealed environment through low-temperature cracking reactions, domestic waste gradually decomposes into three categories: solid carbon residue, fuel oil, and biogas. The solid carbon residue undergoes metal extraction before being repurposed for building materials and soil improvement. The stabilized fuel oil demonstrates industrial fuel value, while purified biogas is recirculated into the equipment's heating system, forming an internal energy cycle. This conversion model maximizes waste resource potential while significantly reducing external energy dependence.

Environmental performance metrics reveal notable advantages. The process achieves substantial mass and volume reduction of residual waste, alleviating landfill capacity pressures. Its clean production methodology avoids secondary pollution from traditional incineration, incorporating heat recovery and gas purification systems to ensure emission compliance. Crucially, the technology demonstrates significant carbon emission suppression effects, providing substantive technical support for China's dual carbon goals.

Designed with urban-rural differentiation in mind, the modular configuration allows flexible processing scale adjustment. An intelligent control system enables 24-hour continuous operation adaptable to varying waste compositions. From residential communities to township processing stations, the technology offers customized solutions. Operational data indicates high energy self-sufficiency levels, reducing operational costs while enhancing system resilience. This environmentally and economically viable model represents a new developmental phase in solid waste treatment technology.

As urbanization accelerates, the widespread application of this equipment will help establish long-term waste management mechanisms and drive the environmental protection industry's transition from terminal treatment to resource regeneration. Future development will focus on optimizing process parameters and expanding byproduct utilization scenarios, contributing innovative solutions to urban-rural environmental governance.

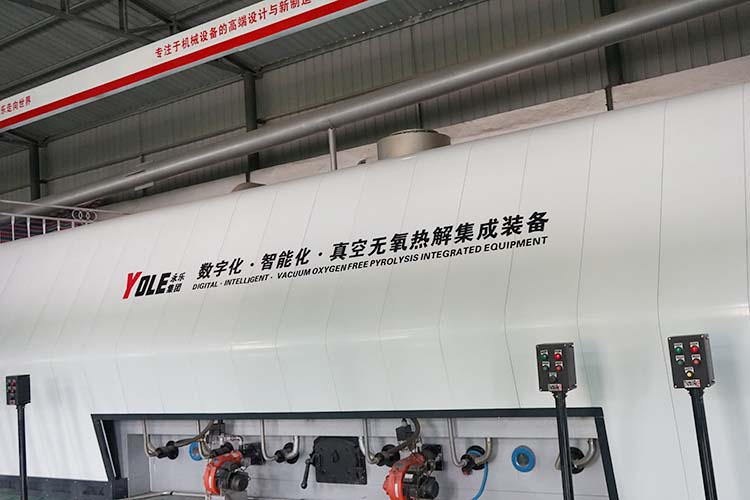

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Waste treatment equipment promotes green and low-carbon transformation,medical waste treatment equipment,YONGLE GROUP

Latest news

Latest news