At present, the main methods for medical waste treatment are high-temperature steaming and microwave disinfection. However, high-temperature steaming and microwave disinfection can only sterilize and disinfect medical waste, achieving harmless treatment, but cannot achieve reduction.

The process adopted by medical waste disposal units is actually two-sided, with the front end being the medical waste generation unit and the back end relying on the incineration unit of household waste. There is no one-stop disposal process throughout the entire process. That is to say, the disposal capacity of medical waste disposal units is limited by the incineration capacity of domestic waste incineration enterprises.

Yongle Group is one of the leading medical equipment manufacturers in China, adhering to the concept of "technology changes life" and continuously promoting innovation and progress in the hazardous waste disposal industry. Based on in-depth research and market demand analysis, Yongle Group has identified the plasma sterilization and disinfection treatment integrated device as a key research and development project.

This device adopts advanced plasma sterilization technology, which can efficiently and thoroughly disinfect medical waste. Compared to traditional steam sterilization and chemical disinfection methods, plasma sterilization has higher sterilization efficiency and lower energy consumption. By fully contacting plasma with medical waste, the device can quickly destroy the cell wall and nucleic acid structure of bacteria, thereby achieving complete sterilization.

In addition, the plasma sterilization and disinfection treatment integrated device of Yongle Group also has the characteristics of intelligence. The device is equipped with advanced sensors and control systems, which can monitor and adjust parameters such as temperature, pressure, and humidity in real-time during the processing. Through automation control, not only can the convenience and stability of operation be improved, but also the risk of human error can be minimized to the greatest extent.

This integrated device is not only suitable for medical institutions such as hospitals and clinics, but also for medical waste disposal enterprises. It can significantly improve the efficiency of medical waste treatment, achieve a one-stop full process disposal, and effectively reduce the risk of environmental pollution. At the same time, the device also has the advantages of small footprint, low noise operation, and low disposal costs, creating a better working environment and higher economic benefits for medical waste disposal enterprises.

Technical characteristics

1. The core of this technology is to instantly decompose medical waste into shapes below 2mm in a closed container, and disinfect and sterilize bacteria and viruses through advanced plasma sterilization technology.

2. Within 15 minutes and at a temperature of 180 ℃ -200 ℃ in a thermal environment, medical waste has a uniform heating, denaturation, deformation, and plasticization with no dead corners on its specific surface area.

3. At the same time, pathogenic microorganisms in medical waste also undergo protein denaturation and coagulation, leading to the death of pathogenic microorganisms (bacteria, viruses) and achieving the destruction and disinfection of medical waste.

4. This technology represents a technological revolution in the traditional mode of medical waste treatment and disposal in China.

Progressiveness process

1. Implement HJ1284-2023 Technical Specification for Operation and Management of Medical Waste Disinfection Facilities.

2. Fully enclosed operation, convenient and flexible operation.

3. Under the premise of safety and environmental protection, achieve long-term uninterrupted and stable operation.

4. The destruction, disinfection, and destruction of medical waste are integrated to achieve harmless treatment of medical waste.

5. Can kill all microorganisms, including bacterial spores.

6. Sterilized items can be wrapped and packaged as a whole, avoiding secondary contamination of viruses and pathogenic bacteria during the unboxing process.

7. Specially made disinfectants are not easy to corrode, and plastics, metals, and rubber are not easy to cause items to turn yellow or brittle.

8. Can penetrate irregularly shaped items and sterilize them.

9. The disinfection temperature is maintained at 180-200 ° C, and there is no odor generated during the disinfection process.

10. Specially designed disinfectants with clear testing reagents for disinfection effects.

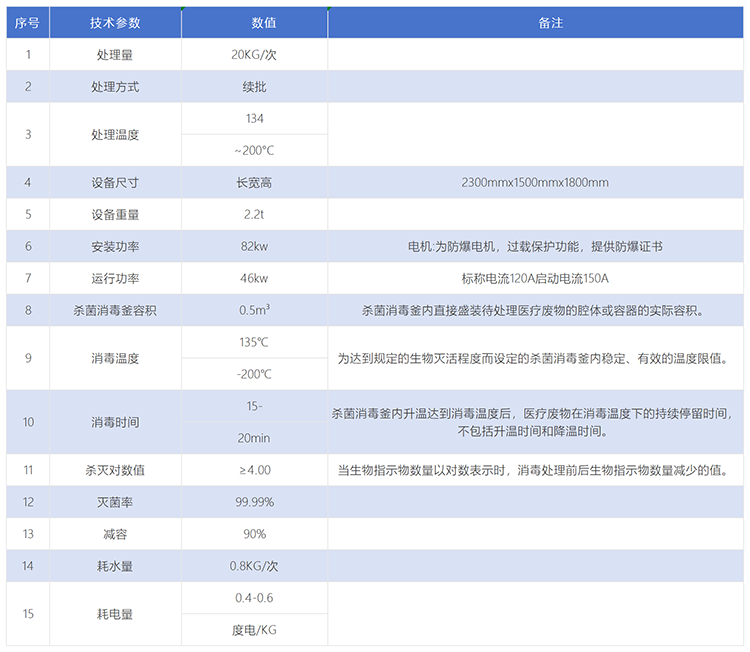

technical parameter

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Integrated device for intelligent treatment of medical waste,intelligent treatment of medical waste,YONGLE

Latest news

Latest news