Yongle Group was founded in 1967 and is the first domestic solution provider to treat waste tires, rubber, and plastics with "fast zero emissions" as the standard. It is a comprehensive large-scale environmental protection engineering and technology company that integrates environmental remediation, technological development, engineering investment, engineering construction, project operation, and engineering consulting. We are committed to providing a complete set of solutions for the harmless, resourceful, reduced, and stable disposal and comprehensive utilization of solid waste and hazardous waste for local governments at all levels.

1、 Waste tires. Characteristics of plastics

① The enormous quantity, diverse types, and complex composition have become prominent issues in the field of environmental protection in China. A large amount of waste tires, rubber, and plastic will inevitably encroach on land, polluting soil, water, and air, and causing other hazards. Waste tires, rubber, and plastics contain almost all substances that can be encountered in daily life, and their composition is quite complex.

② Having relativity between resources and waste. Waste tires, rubber, and plastics may become resources for other products or be utilized by other consumers before being discarded or ultimately disposed of under specific scope, time, and technical conditions, and have the value of waste utilization.

③ The harm has potential and long-term effects. Waste tires, rubber, and plastics may cause environmental pollution at any one or more stages of collection, storage, transportation, utilization, treatment, and disposal. The diffusion of waste tires, rubber, and plastics is small, and their impact on the environment is mainly through water, air, and soil.

2、 Advantages of Yongle Equipment

1. Continuous and efficient.

2. The exhaust gas meets the emission standards.

3. Safe and stable operation.

4. High quality products.

5. Ultra high oil yield.

6. Ultra low cost operation.

7. Low energy consumption and long lifespan.

8. Intelligence and low labor usage.

9. Real time remote monitoring.

3、 Advantages of Yongle pyrolysis technology

1. The pyrolysis process does not require complex sorting and classification, and all types of organic waste can be treated.

2. The system operates completely enclosed and does not come into contact with air, with no conditions for synthesizing dioxins.

3. The non condensable heat value generated by the pyrolysis of waste tires, rubber, and plastics is relatively high, and through recycling, the treatment cost is greatly reduced.

4. It does not require excessive investment in environmental protection equipment to achieve ultra-low emission standards.

5. Cooperate with the Environmental Protection Bureau for 24-hour online testing.

6. Almost no wastewater is generated.

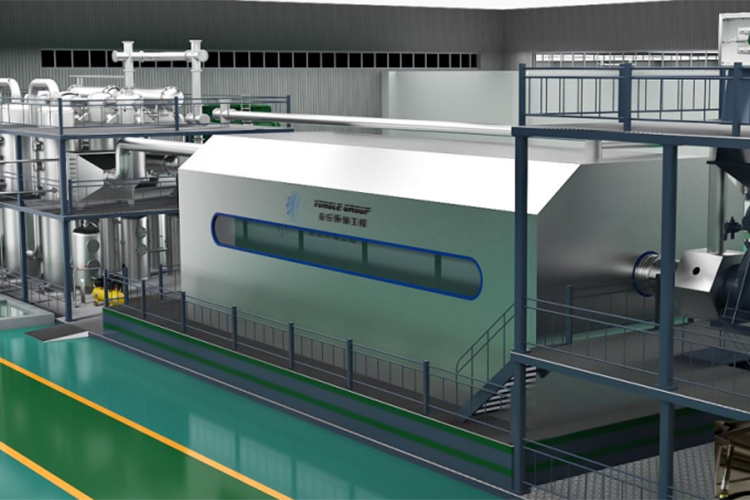

7. Fully automated industrial design, available in large and modular mobile cabins.

8. Provide information and data for technical transformation in cooperation with waste tire, rubber, and plastic disposal units.

9. Provide information and data during the environmental impact assessment process for the disposal units of new and used tires, rubber, and plastics.

4、 Quantum beam environmental treatment system

The pyrolysis quantum beam gas conversion and recycling system is the core of resource utilization. The non condensable gases generated during the pyrolysis process of waste tires, rubber, and plastics contain a large amount of combustible gases such as methane, hydrogen, and carbon monoxide. The conversion and recycling system adopts a "secondary purification energy device" to recycle combustible gases, reduce the generation and emission of pollutants, and lower energy consumption. At the same time, the flue gas emission concentration treated by the "combined environmental protection device low nitrogen burner - rapid cooling+denitrification+deacidification+deacidification washing system+VOCS quantum beam" process meets the national atmospheric pollutant emission standards.

5、 Intelligent control system

The function of an intelligent control system is to achieve the process requirements of the system through a series of control components and control logic instructions. Through intelligent control systems, it is easy to know the operating status of the entire process system, and optimize the process control process by setting and modifying process parameters through an intuitive operating interface, thereby keeping the entire system in a stable operating state.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:Intelligent and resourceful treatment equipment for waste tires, rubber, and plastics,Yongle,Yongle

Latest news

Latest news