We focus on the disposal and comprehensive utilization of organic solid waste.

The main treatment scope includes the following four items: general solid waste such as urban household waste, municipal sludge, and agricultural and forestry straw; General industrial solid waste such as waste plastics, waste rubber, and waste leather; Hazardous waste such as oily sludge, chemical sludge, and refined distillation residue; Medical waste.

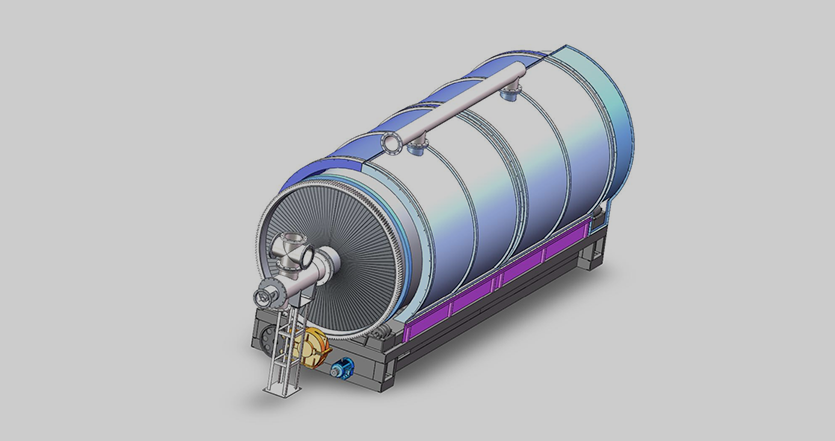

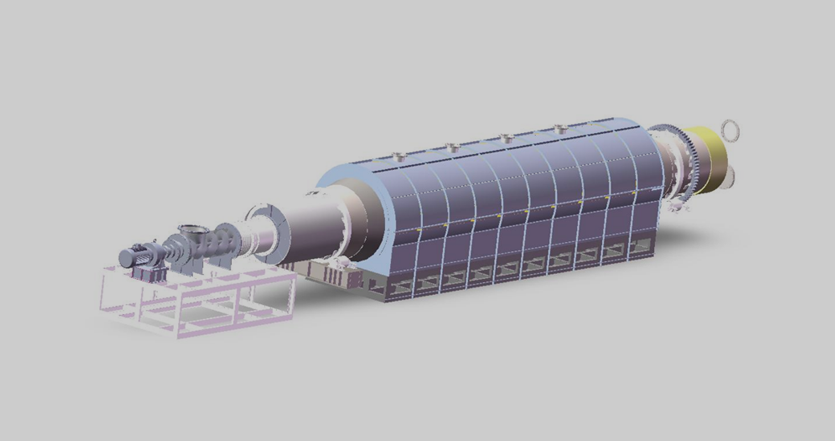

We rely on the group's independently developed "low-temperature anaerobic pyrolysis technology" to focus on the development of two flagship products, namely "continuous batch low-temperature anaerobic pyrolysis" equipment and "continuous low-temperature anaerobic pyrolysis" equipment. Different technical solutions are adopted based on the differences in processing objects and project operation management.

We rely on the group's independently developed "low-temperature anaerobic pyrolysis technology" to focus on the development of two flagship products, namely "continuous batch low-temperature anaerobic pyrolysis" equipment and "continuous low-temperature anaerobic pyrolysis" equipment. Different technical solutions are adopted based on the differences in processing objects and project operation management.