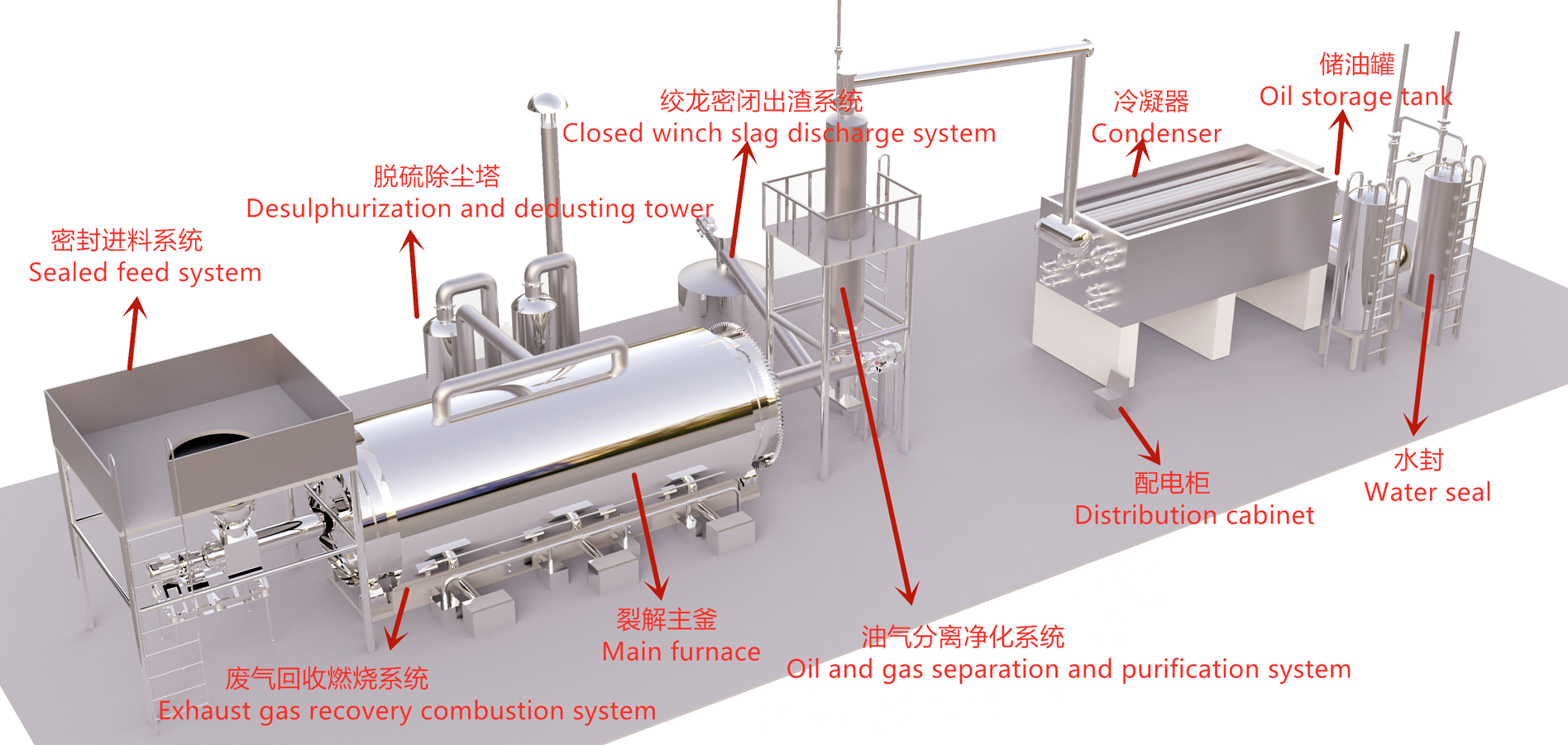

Pyrolysis scheme for oily sludge waste

Regarding the HW08 project, oily soil (071-002-08, 072-001-08) generated from the extraction of waste oil sludge, oil-based mud, natural gas, and crude oil, as well as ship dismantling oil sludge, storage tank oil sludge, pipeline oil sludge, and ship cleaning oil sludge; HW11 (full code) Distillation residue, various high and low temperature coal tar, and waste coke oil residue; HW49 (900-041-49) adsorbs diatomaceous earth and clay with high wax oil; Leather sludge, electroplating sludge, chemi

PLAN INTRODUCTION

Closed transportation, spiral conveying

The oily sludge is transported to the factory area by a closed mud truck, and then to the temporary sludge storage tank in the factory area through docking operations. It is then transported to the mesh cage loading equipment by a screw conveyor, and then to the front buffer compartment of the dry distillation pyrolysis reactor by the screw conveyor. The buffer compartment is connected to the reactor and directly transported to the reactor for pyrolysis reaction by the screw conveyor.

1

High temperature pyrolysis

After being heated and evaporated, the water vapor condenses to form distilled water, which is transported through pipelines to the cooling circulation system for use in the condensation and cooling systems. The pyrolysis reaction time is 6 hours, and the temperature inside the pyrolysis reactor reaches 450 degrees Celsius. The oil sludge undergoes pyrolysis reaction to generate condensable and non condensable vapors, as well as the residue after sludge pyrolysis.

2

Condensing device treatment

Condensable and non condensable gases enter the condensing device through a vapor collection device, where the condensable vapor condenses into water and oil. The condensed water enters the sewage pipeline for sewage treatment and is discharged in compliance with standards; The oil enters the oil collection tank and then enters the combustion chamber for heating through the pyrolysis reactor oil heating pipeline and spray gun

3

Non condensable gas treatment

The non condensable gas enters the non condensable gas purification system for purification through a gas collection device. After purification, the non condensable gas enters the combustion regulator and then provides heat to the combustion chamber through a combustion engine.

4

Weighing and packaging

After sludge pyrolysis, the residue is collected, weighed, and packaged by a carbon cooling device, and sent to the finished product warehouse.

5

CASE