Tire pyrolysis | Plastic pyrolysis plan

The independently developed "waste plastic disposal" vacuum pyrolysis conversion treatment process overcomes the flow technology of solid materials in vacuum pyrolysis furnaces, realizes automated production, and provides technical support for project industrialization, The vacuum pyrolysis technology and device independently developed by the enterprise have met the conditions for industrial application, reaching an international leading level in the field of waste plastic pyrolysis treatment. F

PLAN INTRODUCTION

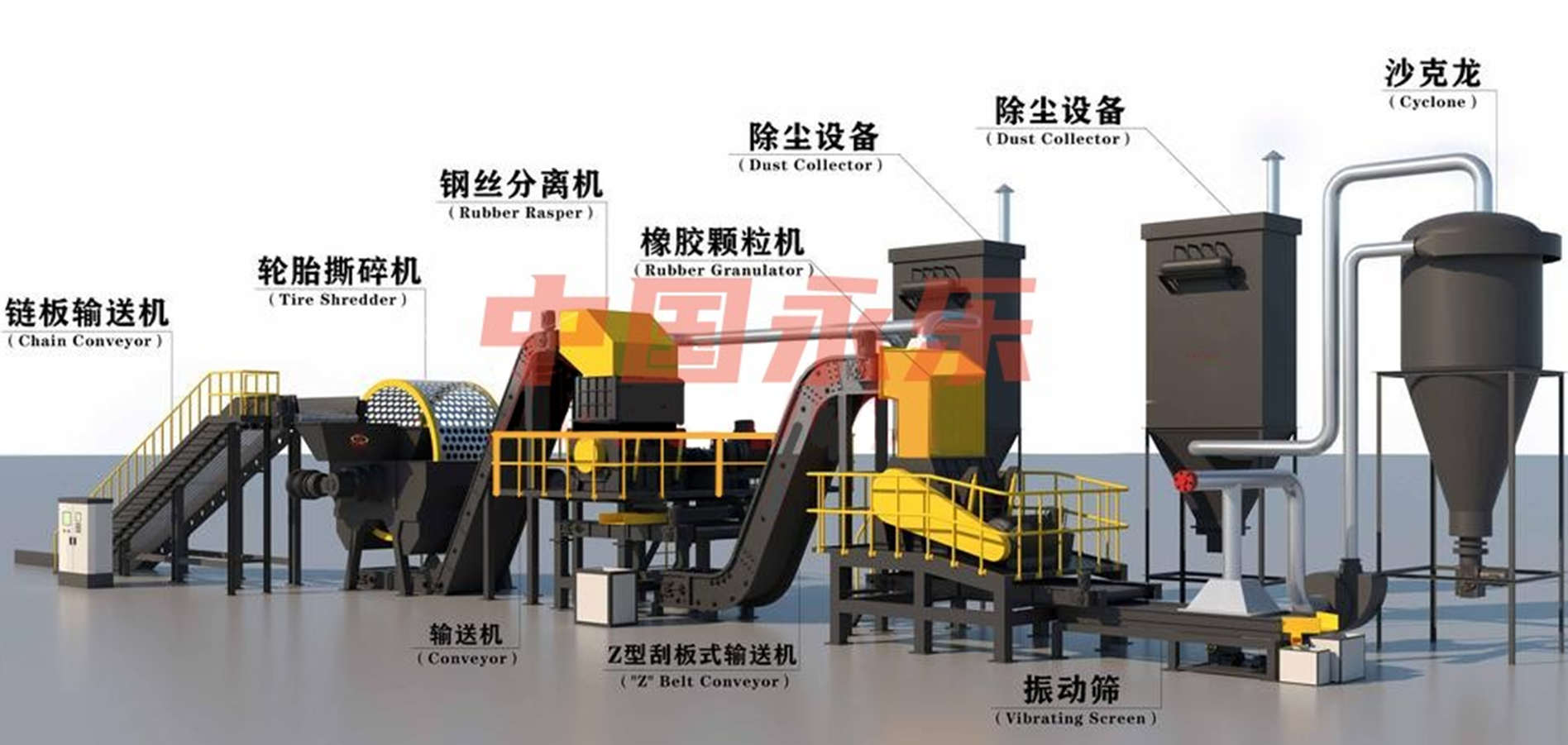

Tire breakage

The tire crushing system peels off the steel wires from the tire (sold as steel) and crushes the tire into rubber particles with a particle size of ≤ 15mm, which are then transported to the rubber particle cracking system.

1

Rubber particle cracking

Using continuous cracking equipment and low-temperature cracking catalytic technology, fuel oil (for sale or reprocessing) and crude carbon black are cracked in a micro negative pressure form.

2

Carbon black iron removal

The automatic high magnetic iron remover further separates a small amount of remaining steel wire debris from the carbon black

3

Efficient and stable

Continuous and efficient, with standard exhaust emissions and safe and stable operation.

4

High quality and low cost

High quality products with ultra-high oil yield and ultra-low cost operation.

5

Intelligent control

Intelligent, low labor consumption, leading remote monitoring.

6

INDUSTRY

Waste plastics

Plastic packaging

Waste rubber

CASE