As a key link in the domestic waste treatment chain, the pretreatment and crushing system plays a vital role. This article will introduce the role, principles and advantages of pretreatment and crushing systems in domestic waste solutions.

Because domestic waste contains a variety of messy items, such as food residues, paper, plastic, glass, metal, etc. Therefore, these wastes must be initially classified and processed before subsequent processing. The pretreatment and crushing system is one of the key equipment used for rough processing and decomposition of domestic waste. Its role is mainly reflected in the following aspects:

1. Garbage decomposition. The pretreatment and crushing system can effectively decompose domestic waste and break large items into smaller particles or fragments, which facilitates subsequent classification and processing.

2. Reduce the volume. Through crushing processing, domestic waste that originally occupied a large space can be greatly compressed, reducing the volume of the waste and facilitating subsequent transportation, processing and storage.

3. Classification and sorting. The garbage processed by the pre-treatment and crushing system is easier to carry out subsequent classification work. For example, separating harmful substances from recyclable substances in mixed garbage provides conditions for subsequent resource recycling.

4. Save follow-up treatment costs. The pre-treatment and crushing system can reduce energy consumption and costs in the subsequent waste treatment process, and improve the efficiency and economy of the entire domestic waste treatment process.

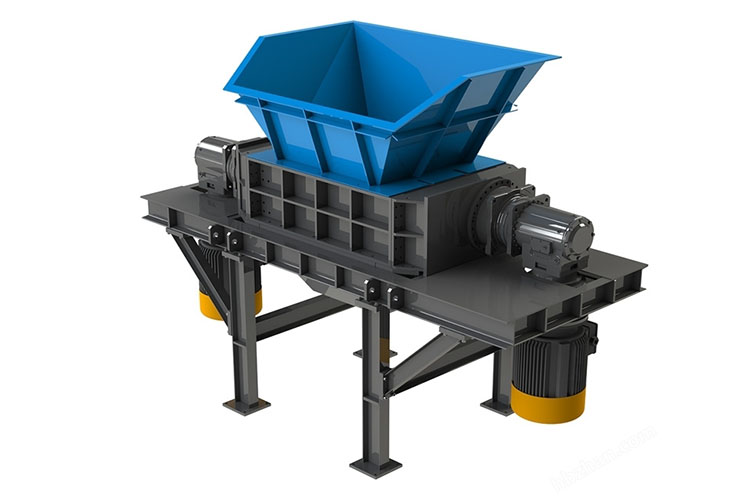

The pretreatment crushing system in the domestic waste solution usually consists of a feeding system, a crushing system, a conveying system and a control system. The workflow is as follows:

1. Send domestic waste into the crushing system through conveyor belts or other methods. The feeding system is usually designed with anti-clogging and protective equipment to ensure that waste can enter the crushing system smoothly.

2. The crushing system is the core component of the entire pretreatment system, mainly composed of crushers, blades, hammers, etc. As the waste passes through the crushing system, blades or hammers break it down and break it down into smaller pieces or particles.

3. The crushed garbage is sent to the next processing link through the conveying system, such as classification, compression, incineration or landfill, etc. The conveyor system usually uses conveyor belts, pipes, etc. to ensure that the crushed garbage can be effectively transported to the designated location.

4. The control system is used to monitor and adjust the operating status of the entire pretreatment and crushing system, including crushing speed, conveying speed, equipment fault detection, etc., to ensure safe and stable operation of the system.

Pretreatment shredding systems offer many advantages in household waste solutions. By crushing domestic waste, recyclable resources such as paper, plastic, glass, metal, etc. can be more fully utilized, thereby realizing resource recycling; domestic waste can be effectively processed and landfill and incineration of waste can be reduced. It reduces the pollution and pressure on the environment and is conducive to the protection and improvement of the ecological environment. ; Improves the efficiency and cost-effectiveness of waste treatment, reduces the operating costs of waste treatment, and has positive economic significance for urban management and resource conservation.

In the future, with the continuous innovation of technology and the in-depth development of garbage treatment concepts, the pretreatment and crushing system will continue to develop in the direction of intelligence, efficiency and environmental protection. At the same time, strengthening the research, development and application of pre-treatment and crushing systems will help solve the many challenges faced by urban domestic waste and promote sustainable development and environmental protection.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Tags:The role of waste crushing system in domestic waste solutions,domestic waste solutions,YONGLE GRPUP

Latest news

Latest news