PRODUCT FEATURES

PRODUCT VIDEO

VIDEO INTRODUCTION

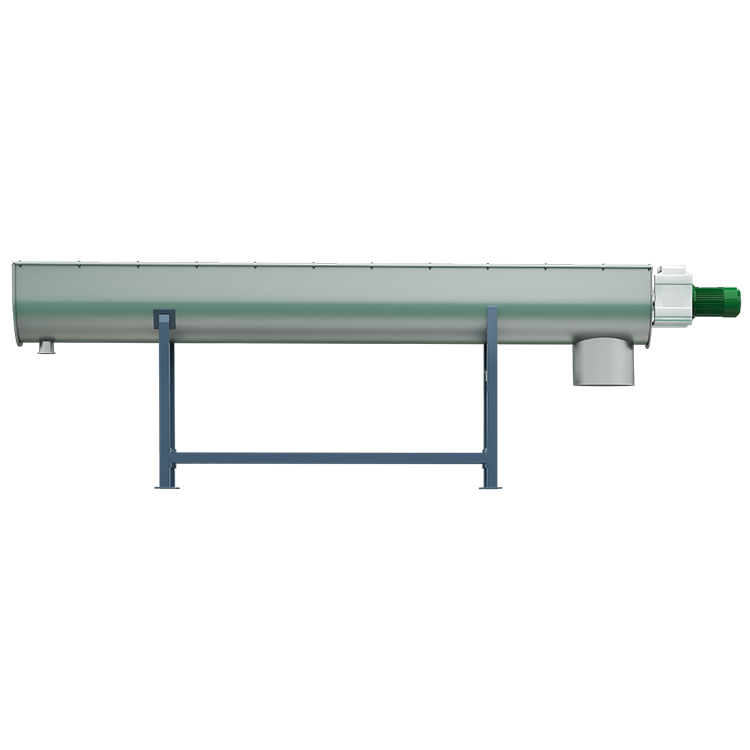

PRODUCT INTRODUCTION

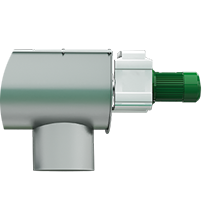

The working principle of a screw conveyor is that the rotating spiral blades push the material through the groove or pipe to obtain the purpose of conveying the material. Loose materials accumulate at the bottom of the groove under the action of their own weight and the friction force of the casing, and are not pushed forward by the blades as they rotate.

01

The spiral blades welded on the rotating shaft of the screw conveyor have different surface types according to the conveyed materials, such as solid surface, belt surface, and blade surface.

02

The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction to provide axial reaction force to the screw with the material. When the machine length is long, a middle hanging bearing should be added.

03

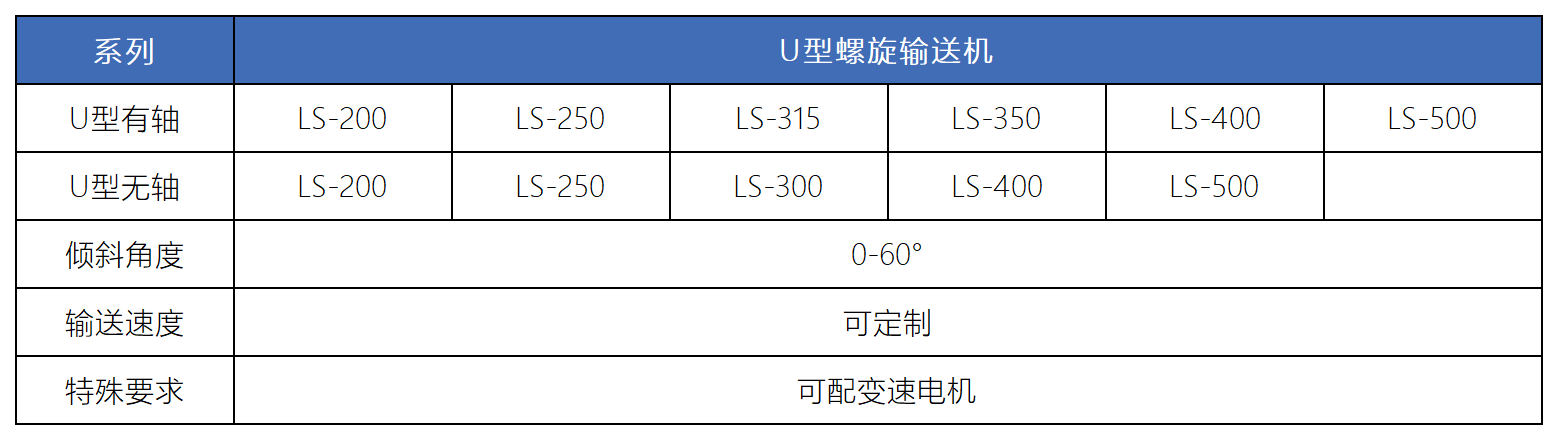

SPECIFICATIONS

U-shaped screw machine

FOR MORE DETAILS, PLEASE FILL IN YOUR PERSONAL INFORMATION AND WE WILL CONTACT YOU AS SOON AS POSSIBLE