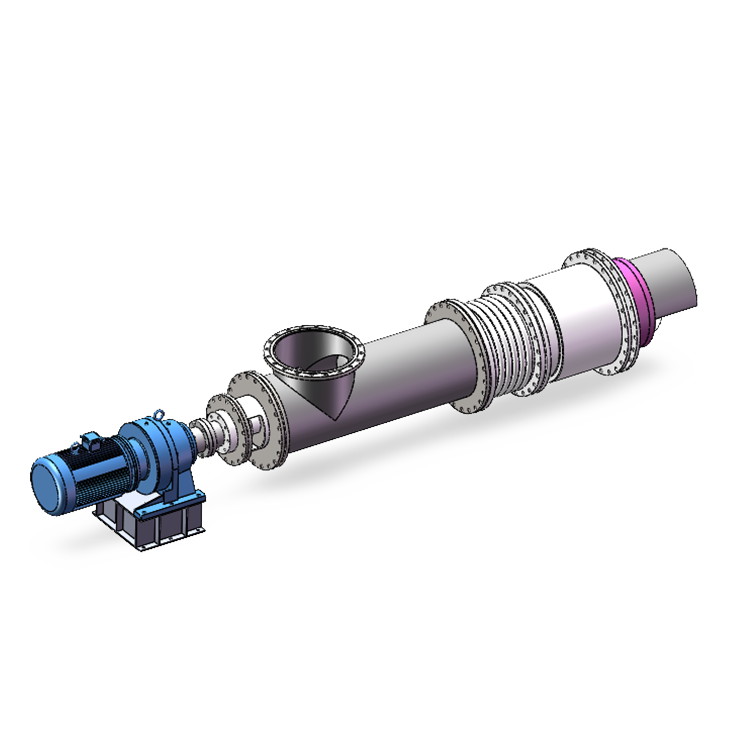

Sealing feed system

The feeding system adopts a feeding sealing system, and the silo is equipped with protective devices. The closed and safe feeding is completed through a screw conveyor. The volume of the silo is 10 cubic meters, and the frequency conversion feeding system has a speed of 8 cubic meters per 2 minutes.

SYSTEM CHARACTERISTICS

SYSTEM DISPLAY

CORE EQUIPMENT