Waste gas treatment system

During the high-temperature sterilization process, a certain amount of gas containing pollutants such as microorganisms, volatile organic compounds (VOCs), and heavy metals can be effectively removed. These gases cannot be directly discharged into the atmosphere and need to be treated. The exhaust gas treatment system in this project consists of high-efficiency exhaust gas filters, pressure instruments, high-temperature steam backflow sterilization systems, pneumatic control valves, etc., and ca

SYSTEM CHARACTERISTICS

SYSTEM DISPLAY

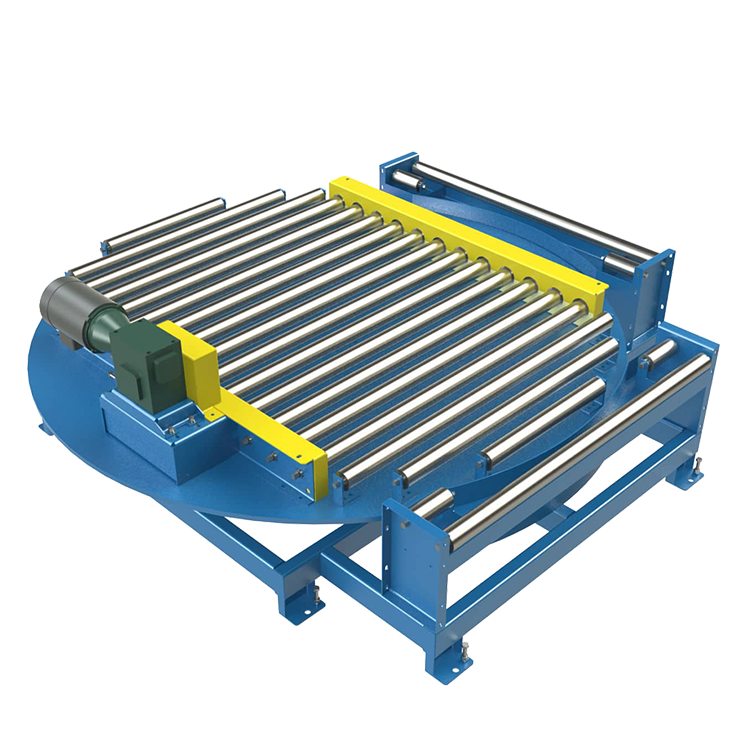

CORE EQUIPMENT