Flue gas treatment system

The flue gas treatment system includes: secondary combustion chamber + scrubber + quenching + denitrification + desulfurization + catalytic combustion + activated carbon adsorption.

The exhaust gas produced by burning pyrolysis gas (bionatural gas) in the combustion chamber needs to be gradually cleaned by a water scrubber, and then processed through quenching, desulfurization, desulfurization, activated carbon adsorption and catalytic desorption, and then discharged through the exhaust pipe.

At

SYSTEM CHARACTERISTICS

SYSTEM DISPLAY

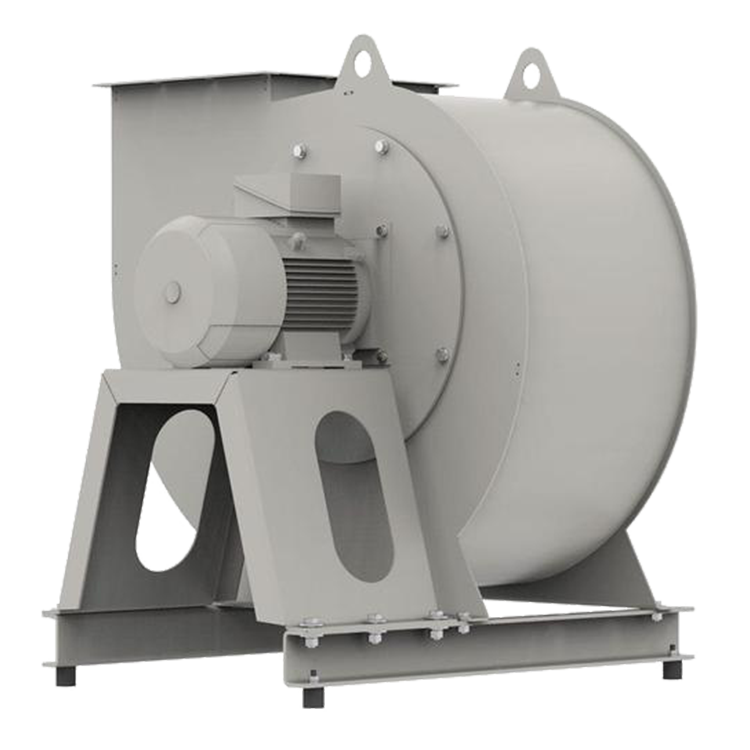

CORE EQUIPMENT