As the amount of waste tires produced increases, waste tire pollution becomes more and more serious. Therefore, it is very urgent and important for the world to find a way to deal with waste tires and prevent or reduce the pollution caused by waste tires.

At present, the most common methods for disposing of waste tires are as follows:

1) Pile to landfill;

2) Recover heat through combustion and incineration;

3) Tire retreading;

4) Recycling waste tires to make recycled rubber;

5) Recycle tires into fuel oil through pyrolysis equipment;

If you’ve done some research into scrap tire recycling, you’ll know that none of the above four methods are great solutions. These processing methods may cause a large amount of waste of these raw materials and also cause serious pollution to the environment. In view of the current situation, the best way to deal with waste tires is to use pyrolysis technology.

Tires are mainly composed of rubber (including natural rubber and synthetic rubber), carbon black and many other organic and inorganic additives (including plasticizers, antioxidants, sulfur, zinc oxide, etc.).

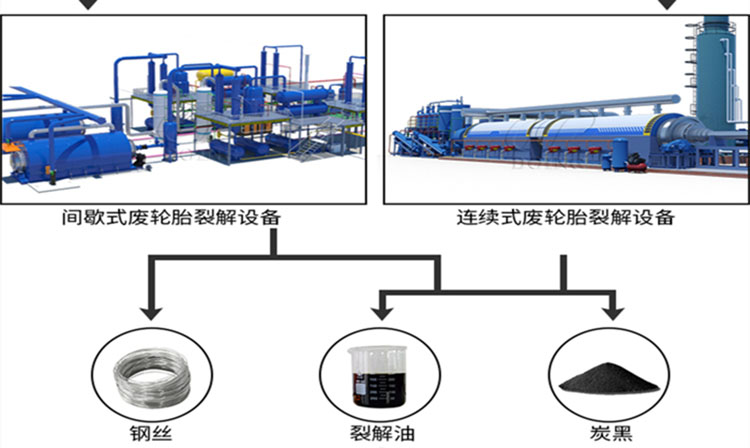

Pyrolysis of waste tires means that in a closed pyrolysis reactor, under appropriate heating, the rubber main chain in the tire is cracked into monomers, biopolymers and fragments, and then polymerized into a variety of olefins, thereby removing volatile substances. The process of obtaining scrap tires. solid carbon. The main end products are fuel oil, non-condensable gases, carbon black and steel wire. Due to different pyrolysis methods, temperatures, etc., the ingredients of each product are also different.

Through the tire pyrolysis process, waste tires can be recycled into renewable energy, fuel, carbon black, syngas, steel wire, etc., without causing secondary pollution to the environment. Dongying Company's new waste tire pyrolysis equipment is equipped with a flue gas purification system, an exhaust gas purification system, a deodorization system and a water circulation system, which does not pollute the air and water.

Tire pyrolysis equipment, including intermittent/semi-continuous/fully continuous pyrolysis equipment. The working process of their tire pyrolysis oil is similar, so how is the high-temperature pyrolysis of tires performed?

First, use a wire drawing machine to remove the tire steel wire. This step is to prepare for shredding the tire; secondly, put the tire without hard steel wire into the tire shredder to obtain small pieces of tire. The shredded tire is easy to pyrolyze; Note: The above 2 steps are not required for intermittent tire pyrolysis equipment, but are necessary for semi-continuous and fully continuous tire pyrolysis equipment.

Feed the shredded tires/whole tires into the pyrolysis reactor through an automatic feeding machine, and heat the reactor with fuel/LPN/wood/coal/natural gas. This step enables automatic loading, thereby reducing labor costs and investment. And the syngas produced during tire pyrolysis can also be used to heat the pyrolysis reactor to save costs.

When the pyrolysis reactor is heated to a certain temperature, oil and gas will be produced, and then the oil and gas will pass through the vertical condenser, horizontal condenser and cooling tower three-stage cooling system, be cooled to obtain oil and enter the oil tank; the oil and gas coming out of the cooling tower The non-condensable gas can be recycled to heat the reactor after being processed by the tail gas purification and deodorization system;

Smoke will be produced when the fuel is burned, which will be discharged after treatment by the smoke elimination system; finally, the carbon black in the pyrolysis reactor can be collected by the carbon screw conveyor;

The above is the introduction of waste tire pyrolysis equipment. Yongle environmentally friendly waste tire pyrolysis equipment can not only process waste tires, but also waste plastic/waste oil sludge.

Yongle Environmental Protection is mainly engaged in the research and development, production and sales of complete sets of technical equipment for organic solid waste disposal and comprehensive utilization. Production and manufacturing, domestic waste treatment equipment, tire pyrolysis equipment, medical waste disposal equipment, hazardous waste disposal equipment, and achieve efficient and comprehensive utilization of resources through independently developed low-temperature anaerobic pyrolysis equipment technology solutions.

Latest news

Latest news